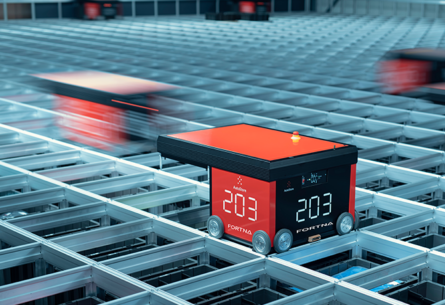

Case Study

Heavy-duty Growth Demands a Heavy-duty Distribution Operation

A privately-held industrial products manufacturer/distributor with $2 billion+ in annual revenues was experiencing double-digit growth. They supply heavyduty tools and accessories for everyone from professional tradesmen and hobbyists to do-it-yourselfers. They also list several big box retailers such as Home Depot, Grainger, MSC Industrial and Ace Hardware as customers.

To better service these customers and expand operations to enable rapid growth, the company engaged FORTNA to consolidate four existing facilities into a new 600,000+ square foot distribution center.